Production Scheduler is the dedicated tool for all manufacturers producing with a process and who need better production planning.

These industrial processes are very often expressed in the form of recipes or formulas. They require operations or steps such as blending, grinding, cooking, mixing, stirring, distilling, heating and/or cooling, or reactive processes, with the insertion of components/compounds at each stage of the process.

Process industries need to schedule according to their own constraints, and are looking to optimize their tanks, lines and reservoirs.

Infor Production Scheduler is a supply chain planning solution that optimizes production resources, meanwhile reducing costs, improving performance and increasing sales:

- Improve scheduler decision-making with more accurate and reliable production planning

- Optimizing supply chain efficiency

- Make on-the-fly adjustments to ensure production schedules are optimized for efficient flow and minimal downtime

Discover Production Scheduler software features

Synchronize your production operations with precision

Manufacturers can simultaneously plan and synchronize operations on all production lines, including interdependencies:

- In this way, they reduce downtime linked to configuration and changeovers.

This type of agile production planning, whether just-in-time or as-when-possible, offers numerous benefits.

In particular, the Production Scheduler module manages recipes, co-products and yield losses.

It also manages vat and tank constraints to obtain the optimum flow of materials and products.

These include :

- variable flow rates,

- fermentation and maturation constraints,

- storage restrictions,

- product-specific filtration and filling constraints, and floating bottlenecks.

The system considers shelf life, overlapping processes and Cleaning In Place (CIP).

React to unexpected events with a dynamic dashboard and indicators

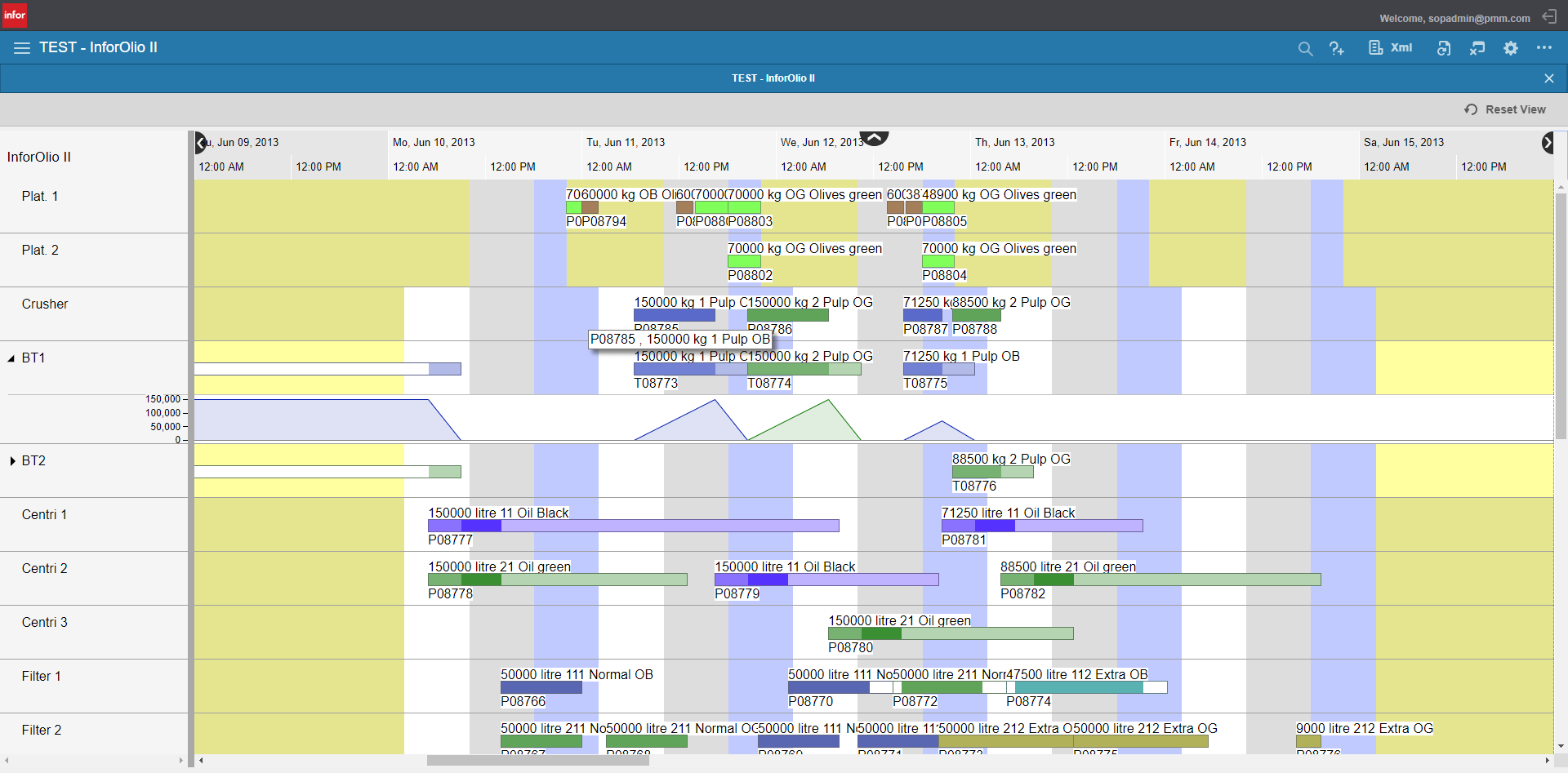

The Gantt chart used for visual scheduling is dynamic.

In fact, it adjusts when last-minute changes need to be made. Particularly when demand varies, priorities change, circumstances call for changes.

Theintuitive interface enables schedulers to judge the impact of a change at a glance. They can then take the necessary action to achieve their objectives.

This makes replanning, modifying and reallocating resources child’s play.

What’s more, all available indicators are also dynamic.

They measure:

- performance,

- cycle times,

- as well as changeover, preparation, maintenance and, of course, production times.

Native automatic system optimization techniques boost system performance.

A word from the integrator

Optimized planning

Infor Production Schedulerbrings a high degree of agility to optimized planning of production operations, with ease of adaptation to the specific constraints of batch process industries.

Optimal consideration of dependencies between operations, processing times, resource requirements and capacity constraints to generate efficient, optimized production schedules.

In addition, Infor Production Schedulerresource optimization improves the use of available resources (equipment, machines, personnel, raw materials, etc.). The software takes into account resource availability schedules and priorities to optimize resource allocation and improve overall production efficiency.

Recipe and formula management

Production Scheduler is a scheduling tool developed with the help of beer brewing manufacturers. As a result, the software perfectly manages recipes and formulas specific to the batch process industries.

It supports the definition and management of recipes, formulas, ingredients, quantities, process steps, processing times, temperatures and more. This facilitates the planning and execution of batch-specific production operations.

Return on investment

Infor Production Scheduler frees planners from Excel-based scheduling. Indeed, spreadsheet constraints are a source of many errors, and limit production planning, especially when re-planning after unforeseen events or changes in sales priorities.

Production Scheduler makes it easy to track key performance indicators (KPIs) to assess return on investment, including :

- Order lead time,

- Non-productive machine downtime,

- On-time deliveries or order satisfaction rate (OTIF),

- The use of resources, whether machines or operators,

- Reducing inventory costs.

Data and handling:

- better data quality,

- simplified data collection,

- the ability to compare results using simulations,

- as well as ease of use for the scheduler and his colleagues.

Benefits of implementing Production Scheduler

Reduce your production costs

Through capacity optimization and constraint-based logic, Production Scheduler optimizes the use of your production resources and facilitates the flow of products between them.

The scheduling engine balances production loads by aligning with resource capacities and limiting machine over- and under-utilization, while minimizing the use of raw materials, semi-finished products and commodities.

Improve performance and customer satisfaction

In addition to reducing costs through better planning, the scheduling module enables :

- track the status of production orders,

- control their progress,

- and visibility on production lead times.

Production Scheduler enables you to efficiently plan, prioritize and sequence production orders to meet customer requirements.

Extensive reporting and performance analysis dashboards make it easy to monitor and identify areas for improvement.

Indicators include production efficiency, resource utilization and cycle times.

Gain visibility and collaboration for optimal financial performance

TheProduction Scheduler interface enables schedulers, internal and external staff to monitor production schedules.

Everything is visible from the Gantt chart with detailed planning:

- lots,

- production stages,

- special production orders.

Each user can set up his or her own Gantt to focus on the part of the process for which he or she is responsible, while retaining the same information as other users.

Thanks to this sharing of information and visibility, decisions can be made to optimize margins while reducing losses.

In addition, the tool enables live monitoring of production status, identifying bottlenecks and intervening in good time to maintain production efficiency.

Finally,Production Scheduler integrates production forecasting capabilities to predict future demand and plan production accordingly.

It helps companies to proactively adjust production schedules to meet anticipated fluctuations in demand.

Integrate Production Scheduler into your company’s IT ecosystem

Natively connected to Cloudsuite SCP, Production Scheduler integrates easily with existing software, including :

- ERP - Enterprise Resource Planning — solutions on the market

- and IT systems such as MES (Manufacturing Execution Systems).

This data exchange ensures the synchronization of production schedules and stock management.

MRP supplies production orders to the scheduling tool according to the availability of materials, which then creates the schedule with the authorized bills of materials, inventory levels, lead times and production schedules.

This integration facilitates the exchange of information between different company departments, such as production planning, inventory management, order management and human resources management.

Infor’s benefits in figures

Infor and the manufacturers who use Production Scheduler have observed the following improvements:

- Increase on-time delivery by up to 5%.

- Reduces time lost due to production changeovers by up to 30%.

- Reduces cycle times by more than 20%.

- Reduces production costs by up to 10%.

- Capacity utilization and throughput increased by 10% to 40%.

Production Scheduler significantly improves performance and supports revenue growth.

Combined with the modules in the SCP suite, Production Scheduler makes all the difference to your competitors.