Planning software — Infor Supply Planning is a powerful tool. Designed to optimize production, distribution and procurement, it improves the performance of your global supply chain.

Thanks to its ability to synchronize the resources of your entire supply chain, this software enables you to optimize production, purchasing and inventory for medium and long-term horizons, based on unique criteria such as :

- production resources

- storage and distribution capacities and costs

- critical manufacturing and/or purchasing routings and BOMs

- fluctuating needs over time

- resource capacities and opening times

- lead times and costs for manufacturing, procurement and distribution

- the carbon costs of transport

Infor Supply Planning is also known as Advanced Planning, Baan Planner or Supply+. It is part of Infor’s Supply Chain Planning suite.

Optimize your finite-capacity lines by modeling your various costs and constraints, using an optimization solver.

A powerful tool for controlling your supply chain

This medium-to-long-term planning tool is essential for companies wishing to assess their supply chain variables and the resulting trade-offs in order to make optimal tactical decisions.

By simplifying the implementation of an optimized plan that satisfies constraints and makes the best use of assets, Infor Supply Planning reduces production costs while :

- optimizing the load on production equipment over the medium and long term,

- simulating exceptional situations to find the best solutions,

- calculating supply chain and production costs,

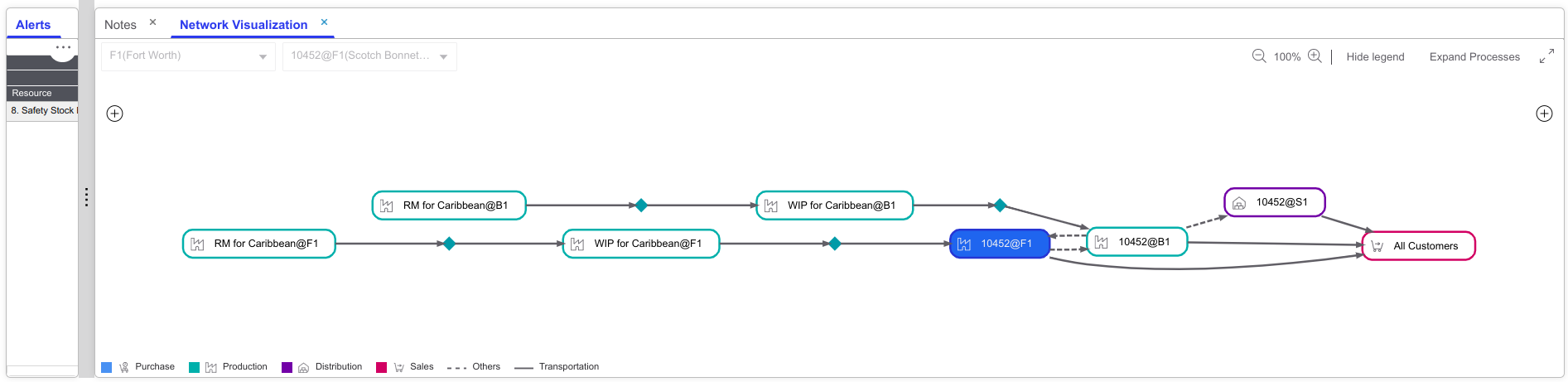

- graphically visualize alerts in the supply chain network quickly and easily

Theadaptability ofInfor Supply Planning to the evolution of your organization is another major advantage :

- multi-site planning: in-house production, subcontractors and warehousing

- take into account shelf-life constraints in anticipation strategies,

- balance the product range,

- choose the best recipe or product formula based on forecasted availability of materials and demand.

Meeting supply chain challenges and minimizing their impact

Effective management of your supply chain is essential to meet the challenges you face.

Among the challenges cited by suppliers:

- rising costs

- efficiency of the production system and lack of capacity

- lack of visibility and collaboration throughout the chain

- insufficient response time and inefficient manual processes

- rising customer expectations

- exacerbation of volatility, complexity and uncertainty

- environmental risks and criteria

These challenges are a real headache.

They also have a significant impact on companies’ costs and sales opportunities , including :

- late deliveries and penalties

- disruptions leading to loss of customers and market share

- fluctuating lead times resulting in lost sales

- exorbitant shipping costs for all modes of transport

- an increase in inventories of certain products to cover uncertainty, leading to more low-margin promotional campaigns or obsolete stocks

- reduced optimization of the production tool: variability and volatility are the causes

Infor Supply Planning meets these challenges by offering a complete solution for optimizing your capacity, materials, inventory and product distribution.

Supply Planning software features

Infor Supply Planning features are designed to model an ideal supply chain that adapts to the changing variables and unique characteristics of your organization.

Now you can organize an efficient, cost-effective supply chain that makes the necessary production trade-offs.

The tool provides optimized supply chain planning for:

- supplies,

- production

- transportation,

- storage,

- distribution.

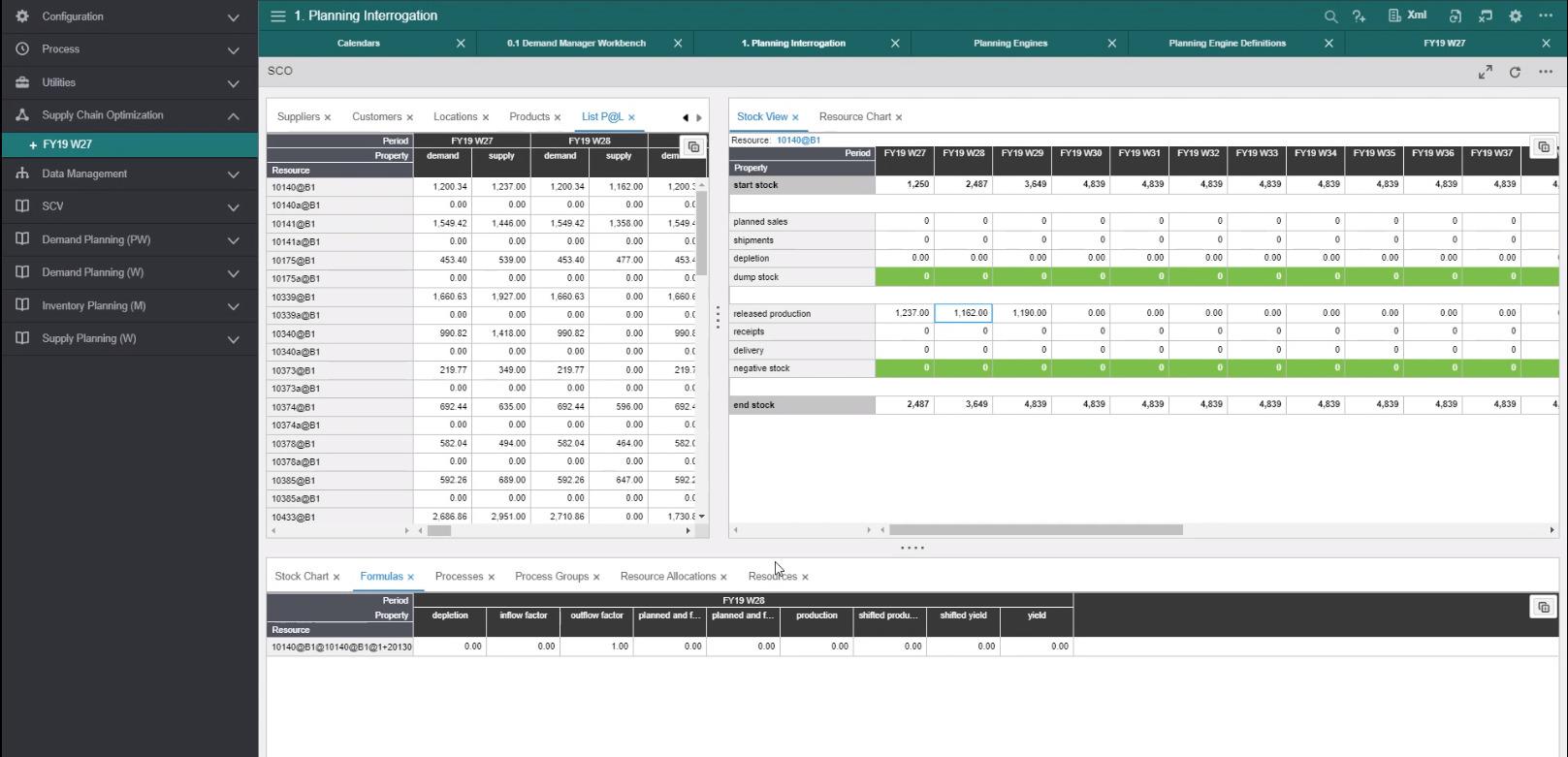

This means you canoptimize your sales forecasts and transform your orders into operational plans for your entire value chain, all in a single tool.

At the same time, the capacities (CRP) are :

- agreement with supply management for trading products or raw materials/packaging components(MRP)

- with a maximized distribution plan(DRP)

Harmonize production and demand over flexible horizons

With Supply Planning, you can efficiently synchronize production with demand over variable time horizons.

In fact, the software plans on multiple, parallel cycles ranging from :

- strategic planning in years,

- to tactical planning in months,

- tooperational in days.

These plans can be automatically reconciled in the tool to visualize costs over several time horizons.

Optimize costs and constraints throughout your supply chain

Infor Supply Planning takes into account costs and constraints throughout your supply chain.

The tool’s native constraint-based analysis engines and algorithms take into account :

- production capacities,

- the various existing sites,

- transport routes,

- hours of available human resources,

- as well as alternative sources of supply.

Also taken into account:

- target stock levels,

- desired service rates,

- product lifespan,

- supply times.

This global optimization makes it possible to direct the use of raw materials according to the constraints of production resources. It also simplifies thesynchronization of production and distribution to meet demand .

Evaluate and adjust your plans with integrated scenario modeling

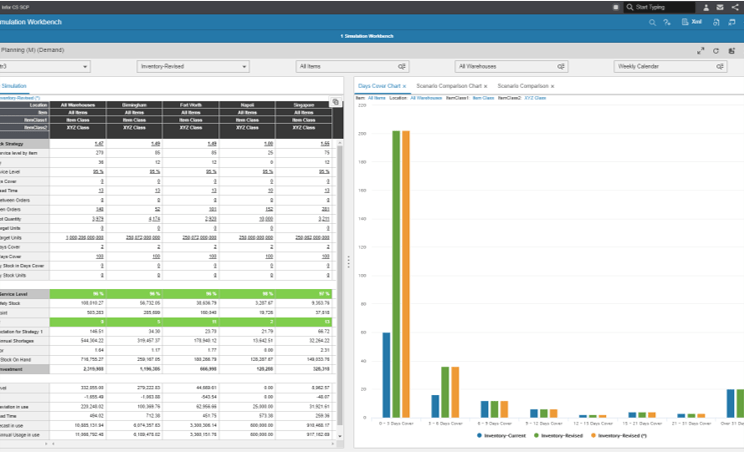

Infor Supply Planning’s integrated scenario modeling lets you evaluate and revise your plans.

Thanks to a what-if scenario simulator, you can compare different strategies and budgets.

A reliable tool to support decision-making, using a variety of levers such as inventory, overtime, alternative sources of supply and “make or buy” arbitration: the software ensures that demand is met.

Rapid re-planning, reactions to contingencies, comparison of strategies to balance supply and demand… all these features are available. The same goes for working with alerts or exceptions.

This feature facilitates informed decision-making at all levels of planning: from strategic to operational.

A word from the integrator

ALOER, integrator of the Cloudsuite SCP solution and Supply Planning module, explains the module’s positive points.

Functional adequacy

Factors such as :

- capacity optimization based on forecasts and demand,

- inventory management functionalities,

- production planning,

- andseamless integration with existing systems to meet specific organizational requirements and processes.

Complete visualization of the supply chain network with alerts highlighted

Easy to install

ALOER believes that the module’s ease of integration into a customer’s existing IT infrastructure is optimal .

The availability of native integration tools in the Infor Supply Chain Planning suite, data compatibility and the need for customization or configuration all meet the needs of organizations.

User experience

ALOER has received good feedback from users for its user-friendly, intuitive interface .

The ease with which planners and users cannavigate the system, enter data, generate reports and access relevant information to make informed decisions is assured.

Performance and reliability

ALOER notes that the module’s performance in terms of speed, responsiveness and stability is excellent in many integration contexts .

The benefits of Supply Planning software

When you use Infor’s Supply Planning software, you benefit from a number of advantages.

Improving production efficiency by optimizing supply chain planning is one of the benefits expected by supply planners, planning managers and supply chain managers, who are behind the introduction of this dedicated software.

Early detection of problems and shorter implementation times

The prescriptive workflow engine makes specific recommendations based on data and probability-weighted projections.

It creates notifications based on :

- workflows,

- tasks and events.

The software uses the solution’s powerful exception management capabilities to improve employee efficiency and ensure compliance with established business processes.

The collaborative platform of the Supply Planning tool can be extended and shared up to :

- remote offices,

- partners, suppliers and contractors,

- and customers.

Solving problems before they slow down or interrupt the smooth flow of the supply chain is made much easier with supply planning software.

Reducing costs and carbon footprint for responsible management

Thanks to theglobal optimization carried out by Supply Planning, cost reductions , particularly in product scrap and waste, are measurable at all levels:

- from raw material to finished product.

Procurement becomes more efficient , with orders as close as possible to the quantities needed. These improvements result in de facto lower inventory, warehousing and transport costs.

What’s more, these reductions are sustainable, even in the event of rapid changes, thanks to the tool’s integrated global optimization.

In addition to significantly reducing costs, the solution supports efforts to reduce the company’s carbon footprint.

Significant increase in profitability

Increased profitability is another benefit of Supply Planning software.

Thanks to optimized inventory and production management, you can optimize capacity utilization and reduce costs, resulting in improved profitability.

Dashboards let you see all your data at a glance.

Efficient inventory optimization

The latest technology calculation engine executes the desired security stock policies:

- by calculating stock coverage levels

- by adjusting both dependent and independent demand

Quick to implement and easy to set up

Whether installed in a multi-tenant cloud or on-premise, you benefit from rapid implementation and easy integration with the other modules in the SCP suite:

- In cloud or SaaS versions, IT teams are freed from managing hardware and software architecture. Technical installation is faster and less costly

- In the on-premise version, IT retains control of the information systems. More flexible possibilities for customizing the tool through specific developments

Supply Planning software can be implemented quickly and customized to your needs.

All SCP Suite modules are natively connected to Supply Planning .

Finally, the project costs associated with integration and configuration remain the same regardless of the type of installation chosen.

Infor’s measurable software benefits

The benefits announced by Infor are remarkable.

According to their statistics, using Supply Planning software can lead to :

- 5 to 30% reduction in inventory

- an increase in service rates of 1 to 5 points

- Capacity utilization increased by 10 to 40%.

- and lastly, a 20% to 50% reduction in planning time.

In conclusion, Infor’s Supply Planning software is the ideal tool for optimizing your supply chain over the medium and long term, improving production efficiency, cutting costs, reducing your carbon footprint and increasing your profitability.

With its advanced features and ability to take into account constraints and changing variables, the software helps you make informed decisions and achieve your planning objectives.